CNC Machining

CNC Machining Service

On-demand CNC machining for rapid prototyping and production parts, through a network of specialized, experienced and thoroughly vetted CNC machine shops.

Our CNC machining capabilities

We operate almost every kind of CNC mill and turning center, and pride ourselves on being able to machine whatever you need, from simple, ‘as-machined’ workholdings to complex, organic geometries with tight tolerances. On request, we can also produce parts with EDM and grinders. Build envelopes, minimum feature sizes and design guidelines vary for milling and turning.

Our network has over 1,000 milling centers, including standard 3-axis mills, indexed 3+2-axis mills & fully-continuous 5-axis mills.

Tolerances from 0.05mm (0.0020 in)

Lead times from 5 business days

Our network has over 300 turning centers, including Swiss lathes and multi-axis mill turns.

Tolerances from 0.05mm (0.0020 in)

Lead times from 5 business days

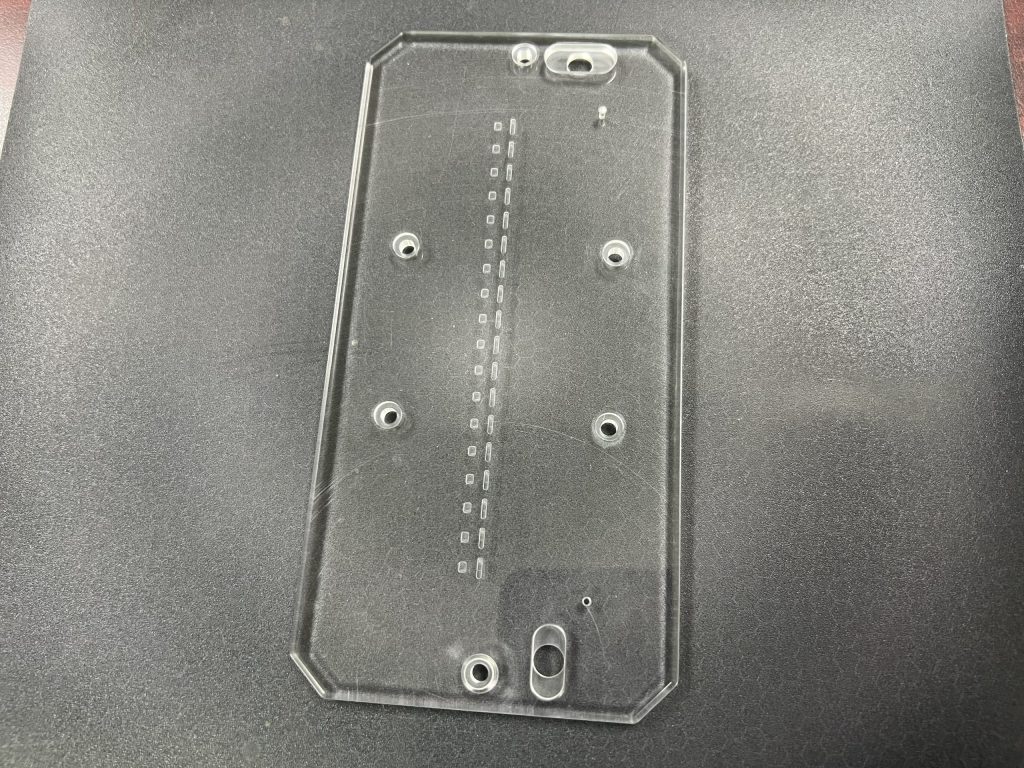

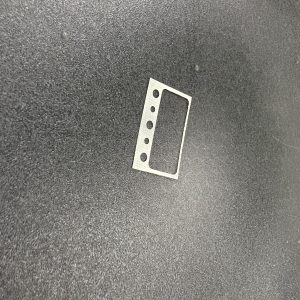

Gallery of CNC machined parts

We machine rapid prototypes and low-volume production orders for customers in multiple industries: aerospace, automotive, defense, electronics, hardware startups, industrial automation, machinery, manufacturing, medical devices, oil & gas and robotics.

The Standard - consistent quality, every time

Takes the stress out of manufacturing by guaranteeing the quality and consistency of every part. Each order is dimensionally and visually inspected by our in-house quality control team to make sure it meets the Standard. If you’re not satisfied with your order, we’ll remake your parts as fast as possible, free of charge, or refund you – whichever you prefer.

Quality documentation

Metallurgy testing, FAI, CMMS & other documents

Threads and tolerances

GD&T and tight tolerances

Inspection standards

Sampling rules, AQL and defects classification

Cosmetic standards

Finishes and visual inspection

Part cleaning & general finishing

Edge breaking, deburring and cleaning

Non standard features requirements

Knurling, part marking and sharp corners